The Problem Statement

The vibration of washing machines often leads to loss of energy that causes inefficiency of the machine. To counter this problem, the client wanted to develop a vision-based washing machine displacement measurement system to check the displacement parameters during operation. If the displacement is more than 5mm, that means the machine is faulty.

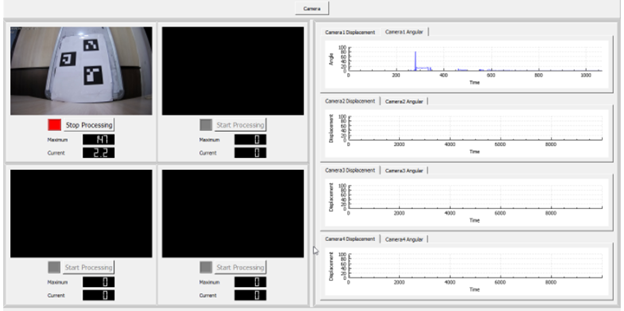

Screenshots

The Solution

KritiKal’s objective was to measure the displacement of the washing machine up to 1mm. The data needed to be collected from each corner of the machine while also measuring the angular displacement.

Apart from Design and Development, KritiKal did a detailed analysis of the camera setup. It had to be mounted on top of the Washing Machine and needed to be:

- Lightweight

- Able to provide enough resolution to ensure accuracy.

We used 3 Aruco Markers on the floor. The camera was mounted on the machine in such a way that it can detect all the Aruco Markers. The Aruko Markers were used to capture the initial and final displacements after turning on the washing machine.

Benefits Delivered

Based on the displacement of the Aruco Markers captured by the camera, the client can efficiently detect the faulty washing machines. This machine displacement measurement system helped to streamline the

Technology Used

- 3D Geometry

- Aruco Marker Detection

- Camera Calibration & Analytics

- Object Detection

- GUI Development

- QT